![]()

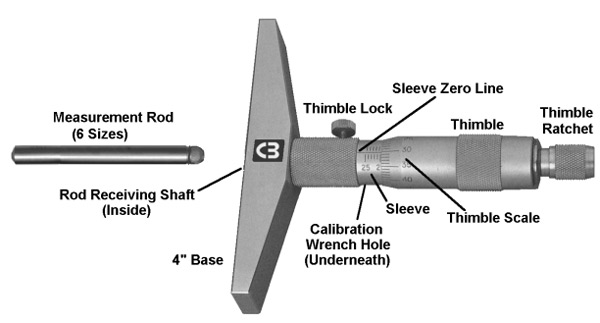

A

depth micrometer is used to measure the depth of holes, slots,

counterbores, recesses, and the distance from a surface to some recessed

part. This type of micrometer is read exactly opposite to the method

used to read an outside micrometer. The zero is located toward the

closed end of the thimble. The measurement is read in reverse and

increases

A

depth micrometer is used to measure the depth of holes, slots,

counterbores, recesses, and the distance from a surface to some recessed

part. This type of micrometer is read exactly opposite to the method

used to read an outside micrometer. The zero is located toward the

closed end of the thimble. The measurement is read in reverse and

increases